EG50 Single Blade Edger

$3,595.00 Original price was: $3,595.00.$2,695.00Current price is: $2,695.00.

Categories Edger & Multrips, Sawmills And Equipments

Tags Blade Edger, EG50

+1(213)267-2305

26 ip4 smatstill Road

mjsawmillslumber22@gmail.com

$3,595.00 Original price was: $3,595.00.$2,695.00Current price is: $2,695.00.

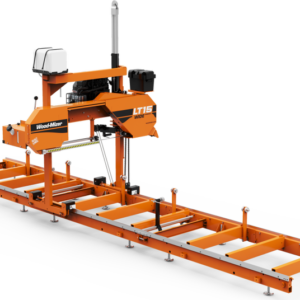

Increase production and profits by turning flitches, sideboards, and slabs into clean square-edged lumber with a board edger. The EG50 is an entry-level single blade lumber edger designed for sawyers who want to maximize the value of every board while minimizing investment. Edging boards one at a time maximizes the value of every board rather than sacrificing usable lumber by gang edging boards on a sawmill. Also save production time by edging boards all in-line without having to set them down and pick them up again.

Operation

A simple pull handle adjusts to any board width in 1/8” increments up to 12” wide. Once the board width is set, flitches, sideboards, and slabs with wane or bark are fed manually through the edger blade. The 10” (254mm) diameter carbide-tipped blade removes one side of the board at a time. For boards that need both sides edged, the material is sent through the edger blade again to square the opposite side of the board. Square-edged boards can also be resized by feeding material through the single edger blade. The EG50 can produce up to a 12” wide square-edged finished board with a maximum board thickness of 2-1/2”.

Features

The EG50 single blade board edger ships on a single pallet and requires minimal assembly. With a 2-year warranty, the EG50 is backed by the same level of service, quality and safety features shared by the entire family of Wood-Mizer wood processing equipment.

One 10” diameter carbide-tipped blade removes one side of the board with each pass

Easily adjusts to any board width in 1/8” increments up to 12” wide

Scale on the in-feed allows operator to measure and edge boards accurately

Engine is removable and outfeed table legs fold flat for storage and transportation

Anti-kickback fingers protect the operator by preventing boards from being kicked out of the edger

Multiple table rollers help move material through the lumber edger

| Quantity | starting at $132/mo |

|---|

| Power Selections | |

|---|---|

| Power Selections | 10HP (7.5kW) Briggs and Stratton gas |

| Cutting Capacities | |

| Min Width of Cut | 2″ (50 mm) |

| Max. Material Thickness | 2.25″ (57 mm) |

| Blade | |

| Blade Speed (RPM) | 3750 RPM |

| Number of Blades | 1 |

| Shaft Size | 5/8″ (15.88mm) |

| Blade Diameter | 10″ (254 mm) |

| Blade Kerf | 0.125″ (3.2 mm) |

| Blade Adjustment Method | Manual Lever |

| Blade position | Fixed on left side |

| Feed System & Operation | |

| Feed Speed | 0 – 46 ft/min 30 ft/min (Gas Version) |

| Board Kickback Prevention | Anti Kick-back fingers |

| Straight Edge Board Fence | Adjustable Board Fence |

| Material Hold-down | Hold-down rollers |

| MultiRip Function | N/A |

| Operator Controls | Control Panel |

| Setworks | N/A |

| Feed System | Manual Push |

| Machine Dimensions & Requirements | |

| Sawdust collection port diameter | N/A |

| Width | 36″ (914mm) |

| Electrical Requirements | N/A |

Daniel Edgeworth –

“The EG50 Single Blade Edger has been a fantastic addition to my sawmill setup. It’s incredibly efficient at cleaning up boards, and the precision is outstanding. I’ve noticed a significant reduction in waste and improved workflow since incorporating the EG50. It’s easy to operate and doesn’t require much maintenance, which is a huge plus for my small milling operation. If you’re looking for a reliable edger that delivers consistent results, the EG50 is a great choice.”

Karen Timberlake –

“As someone running a growing sawmill business, the EG50 Single Blade Edger has been a game-changer. It allows me to maximize the use of my wood, ensuring straight and clean edges every time. The design is simple yet effective, making it easy for my team to use without a steep learning curve. I also appreciate how well-built the machine is—it’s solid and dependable. This edger has increased my productivity and efficiency, and I would recommend it to anyone in the milling industry.”